AGRESLITH-C® is an engineered wood aggregate for lightweight and eco-friendly concrete. It provides weight reduction to concrete slabs without compromising their mechanical characteristics. It is used for constructions and renovations of residential houses, monuments or buildings. Check out our videos and implementation information for quick and easy use.

|

R&D department of AGRESTA developed concrete formulas with wood aggregate AGRESLITH-C® and cement, which are optimized for construction, renovation and interior design.

Properties :

|

Sound absorption : Limits noise pollution up to -55dB(A). |

|

Thermal insulation : Insulates at least 5 times more than conventional concrete. |

|

Low density (Lightweight) : From 500 kg/m3 to 1200 kg/m3. It is up to 4 times lighter than conventional concrete. |

|

Mechanical resistance : Compressive strength easily reaches to 6 MPa and tensile strength in bending is 3,5 MPa. |

|

Hygrothermal balance : Helps to regulate indoor RH (relative humidity) at a comfortable and healthy level. |

|

CO2 fixation: 350 kg of carbon dioxide are fixed in each cubic meter of aggregate. |

|

Fire security : Classified M1 «Non-flammable». It also doesn't release of toxic smoke during fire. |

|

Sawable, screwable and nailable : Allows nail and screw installation without drill or rawlplug. It can be cut with a saw. |

Application areas :

Screed implementation in all types of rooms and on any types of support.

Minimum thickness of screed should be 6 cm and it is suitable for all types of flooring (stone, parquet, laminate, vinyl or carpet flooring).

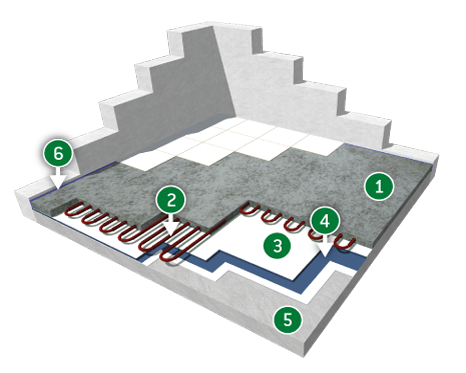

SCREED FOR FLOOR HEATING : SCREED FOR FLOOR HEATING :1. AGRESLITH-C® concrete screed with polypropylene fibers 2. Floor heating system 3. Polyethylene film 4. Under screed insulation 5. Traditional concrete slab 6. Peripheral strips |

INSULATING FLOOR ON COMPRESSION SLAB : 1. AGRESLITH-C® concrete screed 2. Wire mesh panel or pp fibers (Agresfibres) in the screed 3. Polyethylene film 4. Compression slab 5. Peripheral strips |

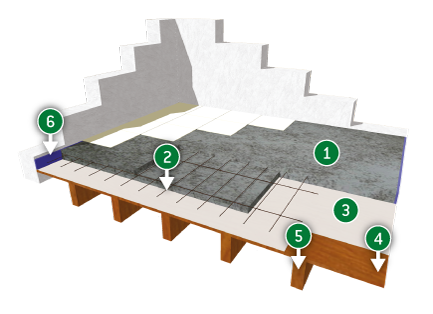

INSULATING REINFORCEMENT SCREED ON OLD PARQUET FLOOR : INSULATING REINFORCEMENT SCREED ON OLD PARQUET FLOOR :1. AGRESLITH-C® concrete screed 2. Wire mesh panel or pp fibers (Agresfibres) in the screed 3. Breathable film 4. Old parquet floor 5. Joists 6. Peripheral strips |

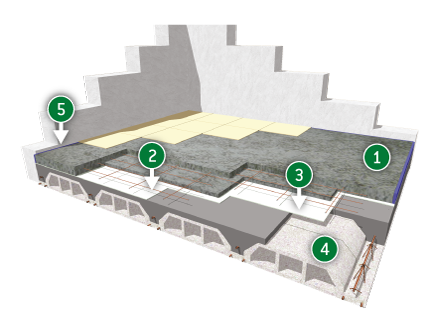

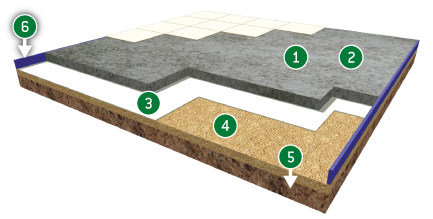

INSULATED SLAB ON SOLID SOIL : INSULATED SLAB ON SOLID SOIL :1. AGRESLITH-C® concrete slab 2. Wire mesh panel or pp fibers (Agresfibres) in the screed 3. Polyethylene film 4. Form of sand 5. Natural soil 6. Peripheral strips |

Dosage and implementation :

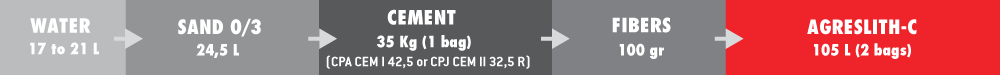

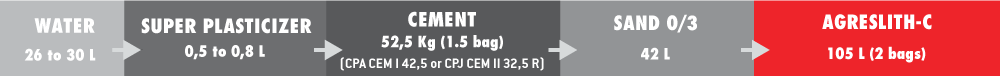

Formula 500 Kg/m3 - Level adjustment

Formula 650 Kg/m3 - Natural lime based

Formula 800 Kg/m3 - Standard formula / Renovation

Formula 1200 Kg/m3 - Floor heating system

1) Put water, sand and cement into the mixer according to the suitable formula.

2) Mix until these elements are homogeneous.

3) Gradually add polypropylene fibers.

4) Gradually add wood chips.

5) Mix in slow rotation.

PRECAUTIONS BEFORE POURING

- Do not pour below 5°C.

- Cover the surface with polyethylene or breathable film (depending on support).

- Ensure that film covers corners efficiently.

- Leave at least 30 cm film in vertical ascent.

- Set up joints (expansion and contraction joints, fractionation and separation devices, etc.).

- Wire mesh panel is unnecessary if polypropylene fibers were added to the mixture.

POURING AND PLACING CONCRETE

1) Pour concrete mix onto your surface.

2) Compact slightly. Compaction must be uniform over the entire surface.

3) Ensure that edges and corners are properly filled.

4) Level the concrete across the entire top surface with a trowel or a smooth flat tool.

5) Optionally spread cement and sand onto the surface to fill cavities.

6) Cover the screed with a polyethylene film for 5 days, then remove it and ventilate the surface.

PRECAUTIONS DURING DRYING

- Do not operate on the slab during curing phase.

- Protect surface from sunlight, air currents and rain.

- Set up control joints 24 - 48 hours after pouring (if has not done before).

Packaging :

3 packaging solutions are available:

|

In Pallets:

|

|

In Big Bags:

|

|

In Bulk:

|

Videos :