LUDOSOL® is a shock absorbing material for playground surfaces. A 25 cm layer of wood chips protects children from serious head injury to a fall of up to 3m. In accordance with European Standard EN 1176-1. It is mineralized in order to be more durable, long-lasting and hygienic. 5 colours are available to make playgrounds more attractive and enjoyable.

|

Properties and advantages :

|

- Easy to install. - Light, clean and dust free. - Fast and economic installation. |

|

- Natural Product. - Raw material comes from forest maintenance works. - Non-toxic to humans, flora and fauna. |

|

- Non-abrasive. - Extends lifetime of equipment, paints and ropes. - Reduces maintenance costs. |

|

- Environmentally responsible production. - Certified by PEFC. - AGRESTA tries to minimize its impact on environment. |

Production method :

Various operations carry out during production phase of LUDOSOL® to provide the highest quality product for both professional and individual usage:

First step is selecting the best raw material which is not previously used to be able to offer pure, unpolluted and consistent wood chips. LUDOSOL® is made by precisely defined and controlled spruce logs. Wood is crushed and sieved to remove any splinters and dust. Wood chips are passed through an oven at a high temperature to remove phenols and tannins which are precursor agents for wood decomposition. Lastly, wood chips are split up according to their particle size of 6 to 20 mm to ensure stability and homogeneity of the product.

In accordance with European International Standard EN 1176-1 : Impact Absorbing Playground Surfaces.

Colour chart :

LUDOSOL® is available in 5 different colours (Yellow, Blue, Red, Green and Natural).

Implementation and maintenance :

Safety and security :

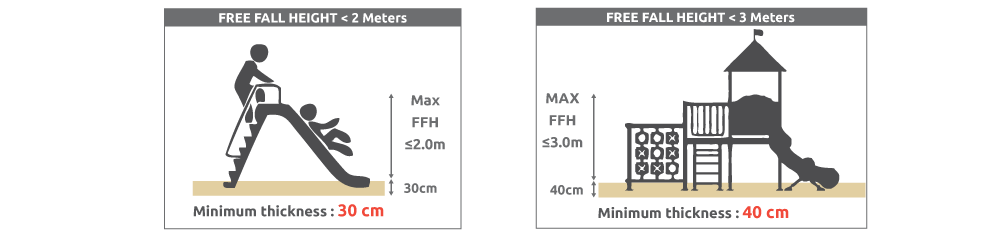

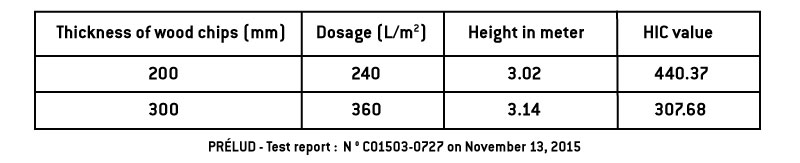

For this study, the thicknesses of 100 mm, 200 mm and 300 mm have been tested to determine the maximum critical drop height (moisture content 35%) according to the thickness of material.

LUDOSOL® has a substantial safety margin in case of breakdown during use.

Packaging :